Air Compressor Manufacturers For Packaging Process,To Power Water Pump, Automobile Shop, Air Compressors For Roadside Repair, Metal Fabrications In Pune

Comprehensive Overview of Air Compressor Manufacturers and Their Applications

Air compressors are indispensable machines that transform power into potential energy stored as pressurized air. They play a crucial role in various industries, facilitating numerous applications that enhance efficiency and productivity. This article delves into the multifaceted uses of air compressors, highlighting key areas such as commercial-grade applications, packaging processes, agriculture, automotive services, roadside repairs, and metal fabrication. We will also touch on Innovair Technology in Pune, a notable player in the air compressor manufacturing sector.

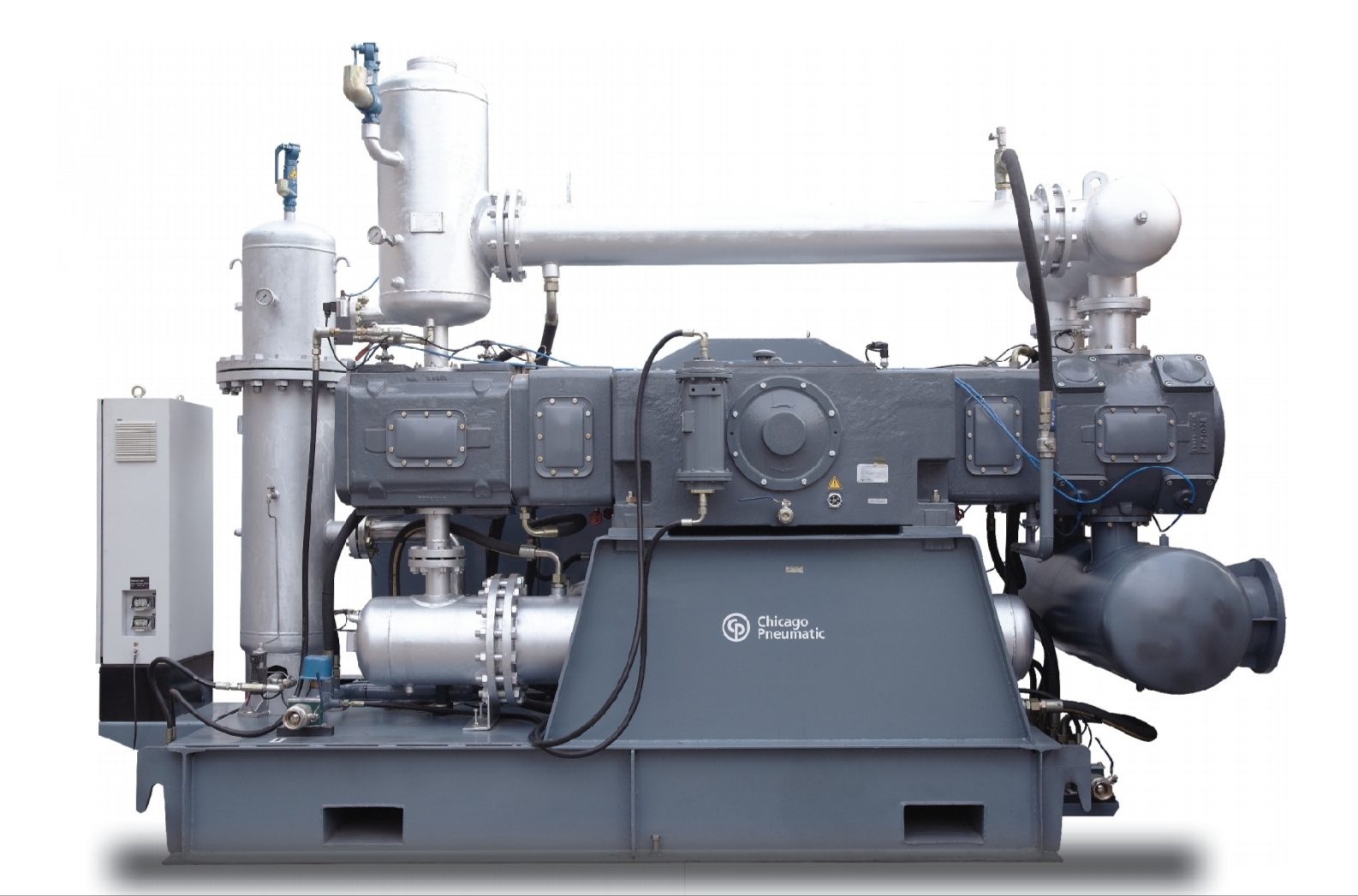

Commercial-Grade Air Compressors

Commercial-grade air compressors are designed to meet the rigorous demands of industrial applications. These compressors are robust and capable of delivering high volumes of compressed air, making them ideal for various commercial needs.

Key Features:

- Durability: Built to withstand continuous operation, commercial-grade compressors often feature heavy-duty motors and components.

- Efficiency: Many models are designed for energy efficiency, helping businesses reduce operational costs.

- Versatility: They can power multiple tools and equipment simultaneously, making them suitable for a wide range of applications.

Applications:

- Manufacturing: In factories, commercial-grade compressors power pneumatic tools, assist in assembly lines, and help with material handling.

- Construction: They are essential for powering air-driven equipment such as nail guns, jackhammers, and air drills on construction sites.

- Food Processing: In the food industry, they ensure cleanliness and efficiency in packaging and production processes.

Air Compressors in the Packaging Process

Air compressors play a pivotal role in the packaging industry. They are used to drive various equipment and processes that ensure products are packaged efficiently and hygienically.

Functions in Packaging:

- Pneumatic Actuators: Air compressors power pneumatic actuators that are integral to the movement and operation of packaging machines.

- Sealing Machines: Many sealing machines, which ensure airtight packaging, rely on compressed air for their operation.

- Labeling and Filling: Compressors assist in the filling and labeling processes, providing the necessary pressure to operate various filling machines.

Benefits:

- Speed and Efficiency: Compressed air allows for faster operation of packaging lines, increasing productivity.

- Hygiene: The use of air compressors in packaging processes helps maintain a clean environment, minimizing contamination risks.

- Flexibility: Air-powered machines can be easily integrated into existing production lines, allowing for scalable operations.

Air Compressors in the Agriculture Industry

In agriculture, air compressors are vital tools that support various functions, particularly in powering water pumps and other essential equipment.

Key Uses:

- Irrigation Systems: Air compressors can power irrigation pumps, ensuring a reliable water supply for crops. This is especially important in areas where water resources are limited.

- Aeration: In aquaculture, air compressors are used to aerate water, promoting healthy fish and plant growth.

- Pneumatic Tools: Farmers use air compressors to power pneumatic tools for tasks such as planting, harvesting, and maintaining equipment.

Advantages:

- Water Efficiency: By powering efficient irrigation systems, air compressors help conserve water while maximizing crop yield.

- Cost-Effectiveness: They provide a cheaper alternative to electric pumps, especially in rural areas where electricity may be unreliable.

- Versatility: Compressors can be used for various agricultural tasks, from irrigation to tool operation, making them invaluable for farmers.

Air Compressors in Automobile Shops

Air compressors have a multitude of applications in automobile repair shops, significantly enhancing service capabilities and efficiency.

Common Uses:

- Tire Inflation: Compressors are essential for inflating tires quickly and accurately, an everyday task in any auto service center.

- Powering Tools: Many pneumatic tools, such as impact wrenches, air ratchets, and sanders, rely on compressed air for operation, allowing mechanics to work efficiently.

- Painting and Finishing: Air compressors are crucial for spray painting and finishing vehicles, ensuring an even coat and professional results.

Benefits:

- Increased Productivity: The ability to power multiple tools simultaneously allows for faster service and turnaround times.

- Precision Work: Pneumatic tools powered by air compressors provide greater control and precision, particularly important in automotive repairs and painting.

- Reduced Fatigue: Air-powered tools often require less physical effort than manual alternatives, reducing worker fatigue and enhancing safety.

Air Compressors for Roadside Repairs and Road Building

Air compressors are essential in roadside repair operations and road construction projects, providing the necessary power for various tools and equipment.

Applications:

- Pneumatic Tools: Road construction and repair require a range of pneumatic tools, including jackhammers, compactors, and concrete vibrators, all of which are powered by air compressors.

- Tire Repair: Mobile tire repair units often utilize air compressors to inflate tires and operate other pneumatic tools required for repairs.

Advantages:

- Portability: Many compressors are designed to be portable, making them ideal for roadside work where mobility is essential.

- Efficiency: Using air compressors speeds up the repair process, allowing crews to complete jobs more quickly and effectively.

- Versatility: They can power a wide array of tools and equipment, making them indispensable in construction and maintenance operations.

Metal Fabrication and Innovair Technology in Pune

Metal fabrication is another critical area where air compressors are extensively used. Innovair Technology, based in Pune, is a prominent manufacturer of air compressors that cater to various industrial needs, including metal fabrication.

Applications in Metal Fabrication:

- Cutting and Welding: Air compressors are used to power plasma cutting and welding equipment, providing the necessary force to achieve precise cuts and welds.

- Surface Preparation: Compressed air is vital for sandblasting and surface preparation, ensuring metal surfaces are clean and ready for further processing.

- Material Handling: Pneumatic systems powered by air compressors are often employed to handle and move metal sheets or components efficiently.

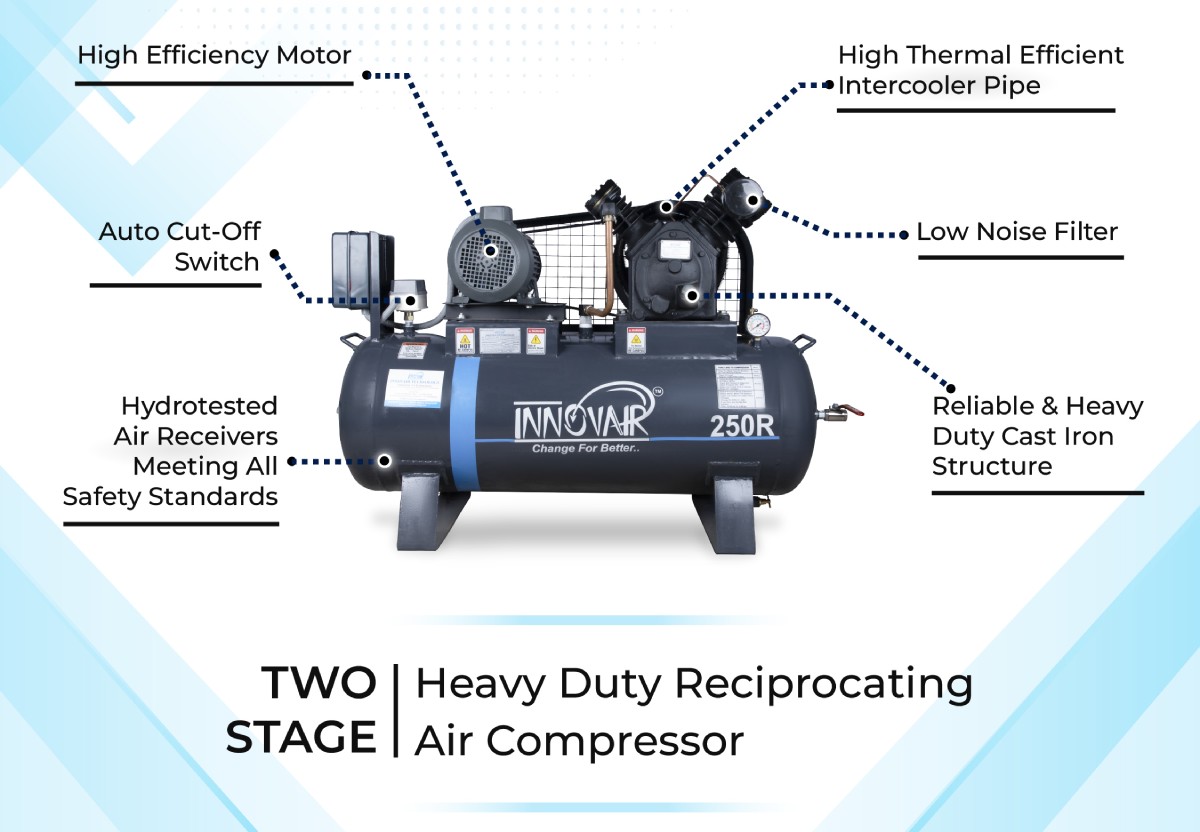

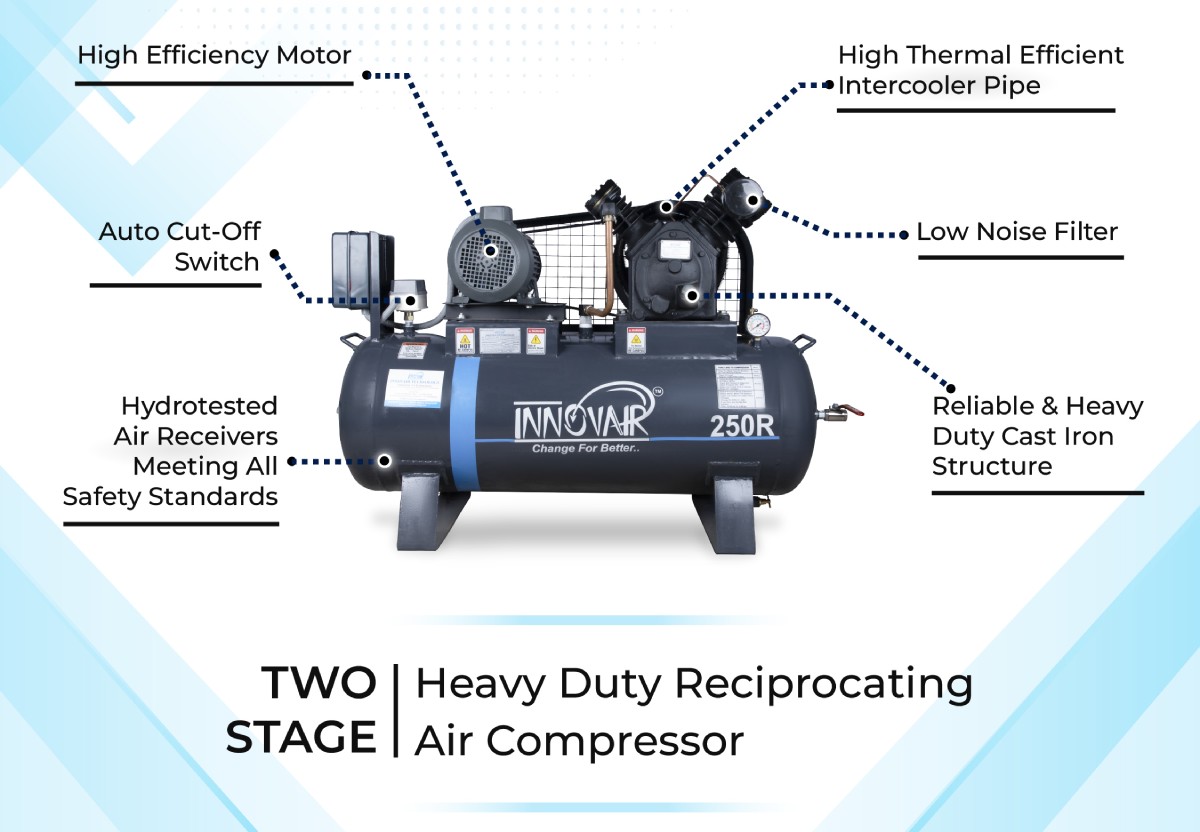

Innovair Technology’s Role:

Innovair Technology is known for its commitment to quality and innovation in air compressor manufacturing. Their products are designed to meet the high demands of industries such as metal fabrication, ensuring reliability and performance.

Key Features of Innovair Compressors:

- Energy Efficiency: Innovair focuses on producing compressors that consume less energy while providing optimal performance.

- Durability: Their compressors are built to last, even in demanding environments, making them a preferred choice for fabricators.

- Advanced Technology: Innovair integrates modern technology into their compressors, enhancing functionality and ease of use.

Air compressors are versatile machines that play a vital role in a wide range of applications across various industries. From commercial-grade compressors powering manufacturing and construction to specific uses in agriculture, automotive services, roadside repairs, and metal fabrication, the importance of air compressors cannot be overstated. Companies like Innovair Technology in Pune exemplify the innovation and quality that define the air compressor manufacturing sector.

As industries continue to evolve, the demand for efficient, reliable, and powerful air compressors will only grow, making them an essential asset for businesses looking to enhance productivity and operational efficiency. Whether in a workshop, on a construction site, or in agricultural fields, air compressors remain a critical component in the machinery of modern industry.